|

Service

Ajinomoto CELLiST Korea is equipped with large-scale production facilities and management systems in compliance with the current Good Manufacturing Practice (GMP). We provide customized manufacturing services of various powder formulations according to customers’ needs, from specifically-customized amino acid mixture supplements to bulk production of commercial growth and feed media.

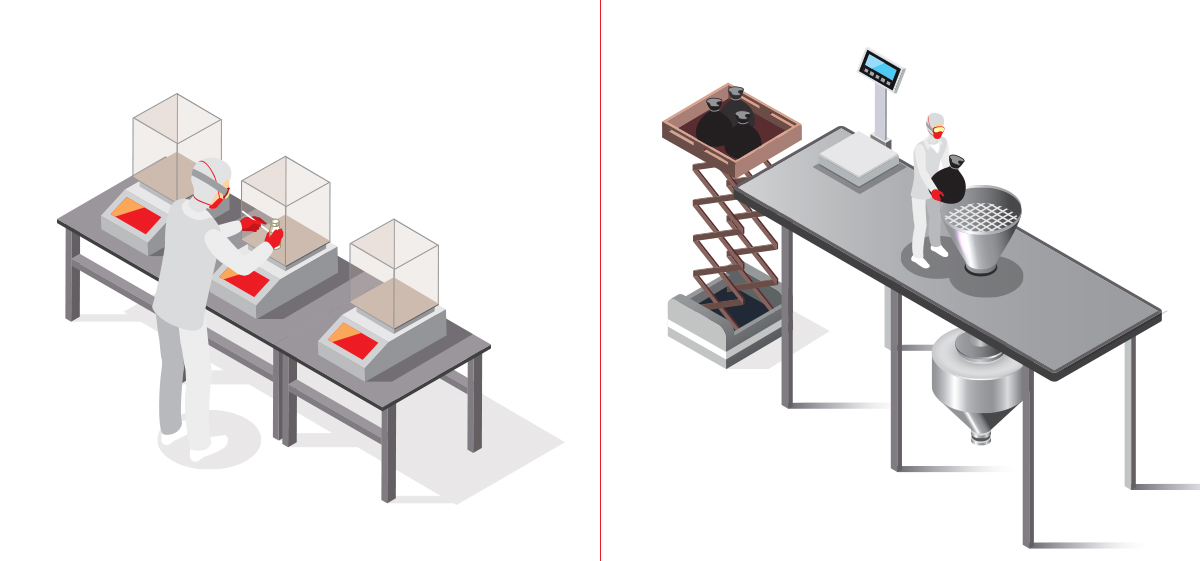

Powder Media/Supplement: powder lots to 10 kg (non-GMP), to 1,000kg (GMP)

| Container (L) | 5L | 10L | 20L | 80L | 250L | 1,000L | 2,000L |

|---|---|---|---|---|---|---|---|

| non-GMP | ~2kg | ~5kg | ~10kg | ||||

| GMP | ~10kg | ~50kg | ~100kg | ~450kg | ~1,000kg |

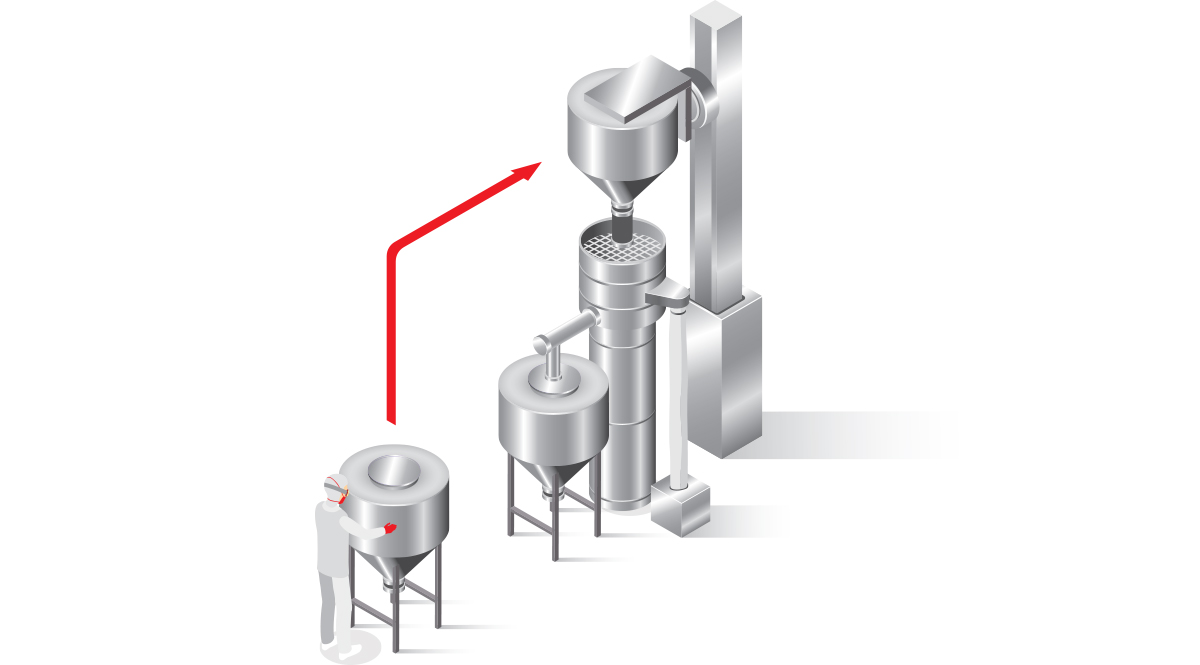

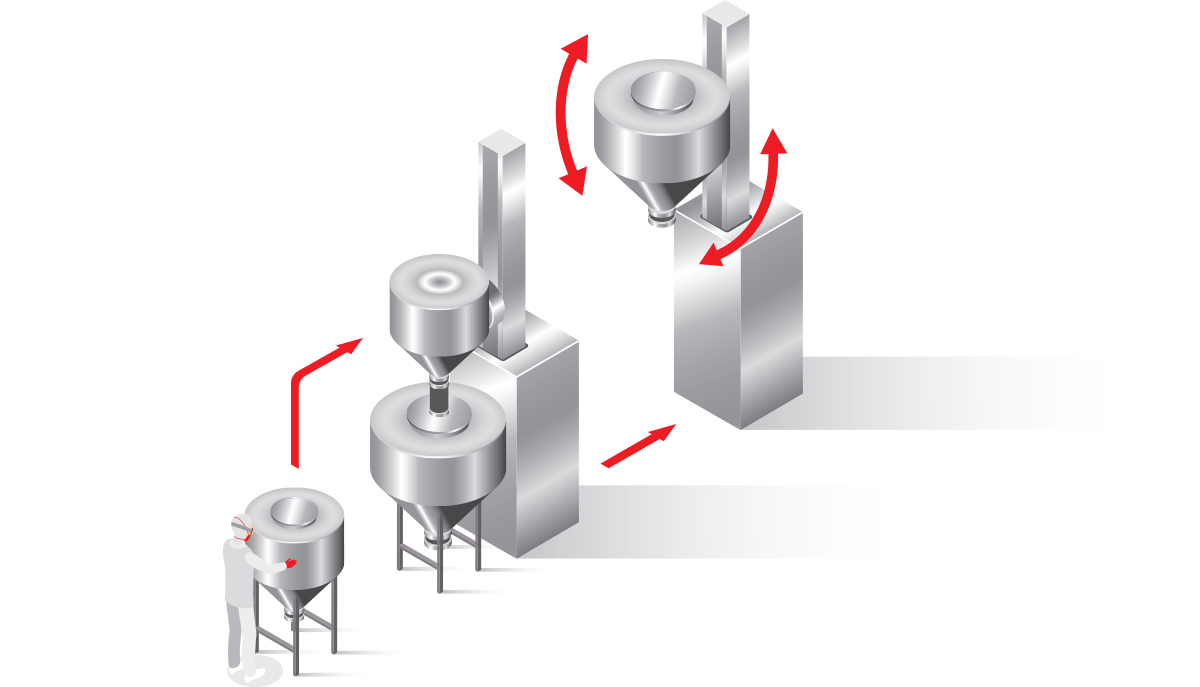

Annual maximum production capacity: 200 ton (1 ton x 200 batches)

Various kinds of formulas includes:

Customer-developed formulas

Classical formulas with or without modifications (e.g. DMEM with low NaCl)

Media are packaged in aluminum pouch or plastic pail by weight

| Aluminum pouch | 6L Plastic drum | 20L Plastic drum | 60L Plastic drum | |

|---|---|---|---|---|

| Amount(kg) | ~0.050kg | ~3kg | ~10kg | ~20kg |

| Amount(L) | ~1L | ~50L | ~500L | ~1,000L |

Product quality are evaluated by the following tests

Result of Analysis is available for prototype.

Testing includes Appearance, Solubility, pH and Osmolality.

TAMC/TYMC, Endotoxin, Mycoplasma and Cell culture are optional, requiring more lead-time to the delivery.