|

Product Basal Media

细胞培养基

Ajinomoto CELLiST Korea生产的用于CHO细胞系的CELLiST™基础培养基是基于味之素在氨基酸技术方面的强大能力和30多年的细胞培养基业务经验而开发的。 CELLiST™培养基是高性能、化学成分明确的培养基,不含任何动物源性成分。

培养基提供氨基酸和其他营养物质的最佳平衡,以确保细胞充分地生长和工艺效率最大化。BASAL CHO MX培养基是完全化学定义的,不含任何动物来源的成分。

| Model No. | BASAL CHO MX |

|---|---|

| TYPE | Powder |

| Concentration | 23.0g / L |

| With Additives | D-Glucose · Poloxamer |

| Without Additives | L-Glutamine · Sodium hydrogen carbonate · Thymidine Hypoxanthine · Insulin and other growth factors |

| Storage Condition | 2℃ to 8℃, dark and dry |

| Shelf Life | 24 months |

| Item Description | Powder, chemically defined and animal derived component free medium, rehydrate to 1 L |

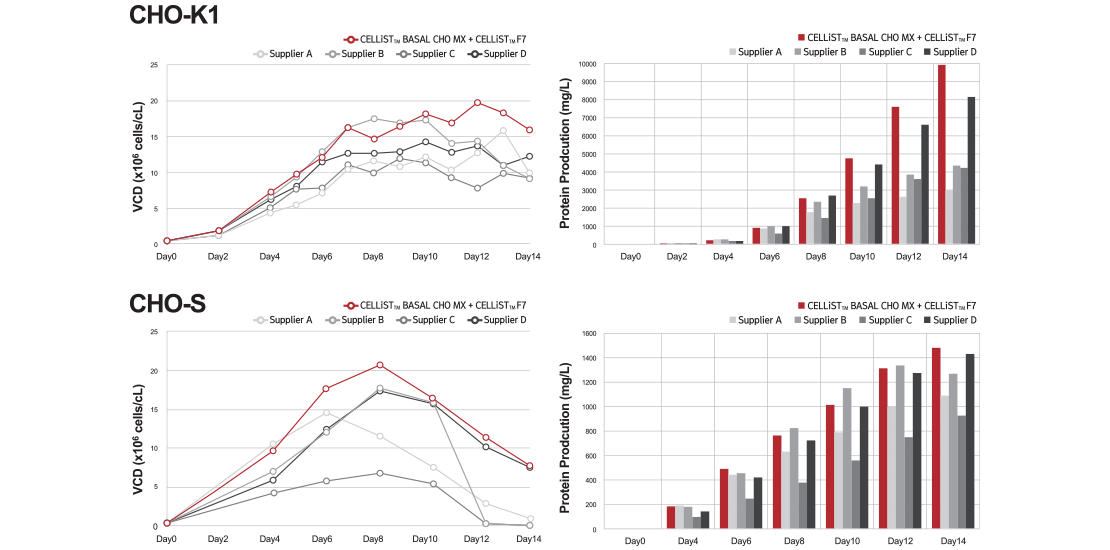

Comparative studies show superior culture growth and productivity with the CELLiSTTM BASAL CHO MX + CELLiSTTM F7 media combination. In a fed-batch process using CHO-K1 and CHO-S cell lines expressing IgG1 antibody, our media outperforms top global competitors in viable cell density and IgG titer.

Figure 1: Fed-batch process was performed in an Ambr®15 system (CHO-K1) and 125 mL flasks (CHO-S), respectively. Feeding in CELLiSTTM group was performed at a concentration of 6% (v/v) on days 4, 6, 8, 10, and 12. ‘Supplier A, B, C and D’ represent basal/feed media combinations from major media suppliers. Culture and feeding manners for supplier A, B, C and D were performed according to each manufacturer’s recommendations.

Scalability

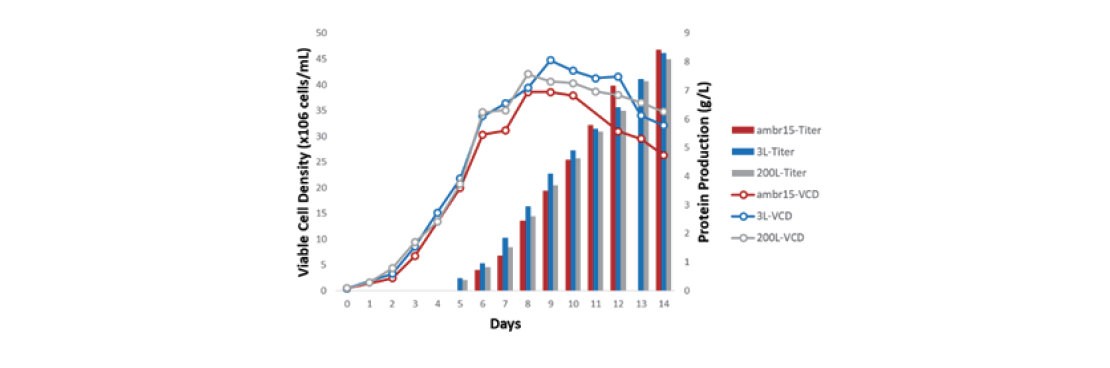

As can be seen below, CELLiSTTM BASAL CHO MX medium is suitable for use in various culture scales

from small scale microbioreactors to larger scale 200L bioreactors. CELLiSTTM BASAL CHO MX medium

shows consistent performance in terms of cell growth and productivity regardless of scale.

Figure 2. Viable cell density and IgG titer profiles during the 14 days of fed-batch culture. Three types of bioreactors were used: microbioreactors (Ambr®15), 3L bench-top reactor and 200L bioreactor.